Functional modeling

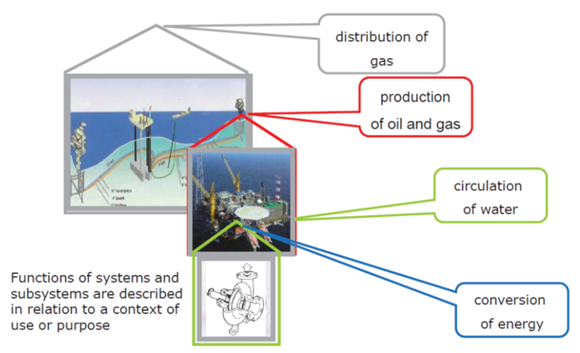

Concepts of functions are fundamental to engineering and to our understanding of artefacts. As an example, we can describe an oil and gas supply system on many levels of functional abstraction. On a high level, its function can be described to be “to supply oil and gas”. On a more detailed level, focusing on one platform, the function is “to produce oil and gas”. On a further level of detail, a subsystem of the platform has the function “to circulate water”. On an even deeper level, the functions of the water circulation pump can be described as “to convert energy”.

This ability to represent complex system on several levels of abstraction can be demonstrated in all engineering domains. Common to all domains is also that means-end relations relate the levels of abstraction: the conversion of energy (the pumping) is a means for water circulation (the end or purpose of the pumping).

Multilevel Flow Modeling

Multilevel Flow Modeling (MFM) is a solution to modelling problems in design and operation of highly automated plants and human-machine systems. It includes a specialized and extensive range of function concepts capturing both the particular characteristics of process automation and addressing cognitive aspects of human-machine interaction. The focus is on plant goals and functions, providing a methodological way of using those concepts to represent complex industrial plants.

Mass and energy flow

MFM models the physical system by representing the mass and energy flow. These concepts can be applied on many levels of physical aggregation which means that, no matter the choice of modelling boundary, the basic laws for mass and energy balance across the modelling boundary still apply.

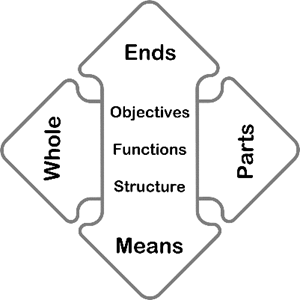

Means-end and part-whole decomposition

Decomposition is necessary for analyzing a complex system. There are two types of decomposition:

- Part-whole decomposition

- Break the system into subsystems, subsystems into components

- Look at the connectivity between components and subsystems

- Means-end decomposition

- Look at the system’s objective (end) and how the objective is realized by different functions (means)

MFM models use both of them, decomposing a system by using the means-end dependencies to guide the part-whole break-down.

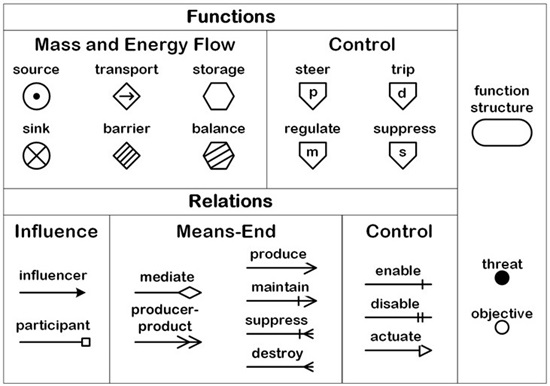

Modeling concepts

The basic MFM modeling concepts comprise objectives, flow structures, flow and control functions, a set of means-end and influence relations representing purpose related dependencies between functions and objectives and among the functions themselves. The symbols used are shown in the figure below.

See how to build a model in this example.

If you are interested in more in-depth information, find a list of recommended publications here.